On a production site of 22 500 m², we are able to store up to 100 containers, ready to be modified. Our site includes:

A workshop of 3750 m², with 3 different areas:

|

|

|

|

|

|

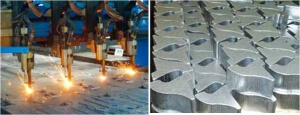

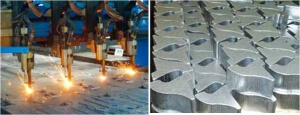

OUR PRODUCTION MEANS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On a production site of 22 500 m², we are able to store up to 100 containers, ready to be modified. Our site includes:

A workshop of 3750 m², with 3 different areas:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|